We are focused on VCSEL and VCSEL pumped solid state laser. VCSEL is more reliable, robust and cost-effective than traditional diode laser (laser bar) and very suitable for pumping solid state laser. This mail includes VCSEL structure, VCSEL array processing, VCSEL characteristics and VCSEL array applications.

VCSEL structure

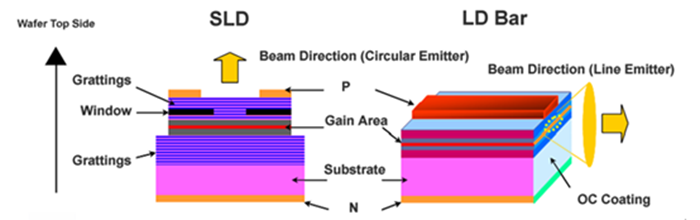

VCSEL is an abbreviation of Vertical-Cavity Surface-Emitter Laser. In our company we call it SLD for short. A typical VCSEL device (Left) is shown above. It contains n-contact (Negative electrode), GaAs substrate, n-DBR (grattings), gain area (quantum well), window (oxide aperture), p-DBR (grattings) and p-contanct (Positive electrode).

There are four differences between VCSEL and edge-emitting laser diode (LD Bar).

First the cavity mirrors. A laser needs 2 mirrors to resonate. In LD Bar the front face is ordinary coating (T=50%@808nm); the rear face is HR-coating,. The laser spectrum depends on the gain linewidth and mode-competition. Usually the linewidth of LD bar is 4 nm (FWHM). While VCSEL uses DBR as cavity mirror and the laser wavelength can be locked. The spectrum of signal emitter is about 0.1 nm. The spectral of VCSEL array, which has 10k emitters, is about 1 nm. Because of the DBR, the wavelength-temperature coefficient is no more than 0.07nm/℃, compared to 1nm/3℃ in LD bar.

Second the gain medium size. Edgeing-emitter usually has a size of 1um X 10um X (1mm, 2mm, 4mm, cavity length). The peak power at the front face is near 1MW/cm2 and the laser induced damage is a problem, which limits the lifetime and the peak power of laser diode. However in VCSEL the emitter size is an 30um aperature and the peak power is very low. There is no laser induced damage at all.

Third the electrode contact. LD bar is a sandwich of Metal-Semicondutor-Metal. The thermal expansion index of copper and GaAS do not match. In QCW mode it leads an alternating thermal stress. The stress fatigue will damage the contact and fails the device. This limits the device lifetime. While in VCSEL the electrode is coated on the surface and the device is very thin, only several micrometers. On the other hand the gain medium is contacted with semiconductor (DBR) and they have similar thermal expansion index. So thermal stress is not a problem in VCSEL. It makes the VCSEL is very reliable in QCW mode. QCW lifetime can reaches 20G shots and we guarantee 5 G shots at least.

Four the manufacture cost. LD bar processing is very complex, including substrate, epitaxie, laser processing, facets cleaving, sigle chip preparation, mounting and bonding. Mounting and bonding is a labor-intensive work. The performance of the device can only be tested after final mounting. The defective products can not be rejected during processing. While in VCSEL manufacturing, everything is automated. Emitter test can be done on the wafer. Defective products can be removed in time to avoid time waste. The product quality (wavelength, power, life time ) are easy to maintain. So the cost is related low.

A small secret in our product. After epitaxy we remove the substrate to minimum the thermal resistance and increase the laser efficiency.